Functional Coating Position:Home > Products > Functional Coating >

- Detail

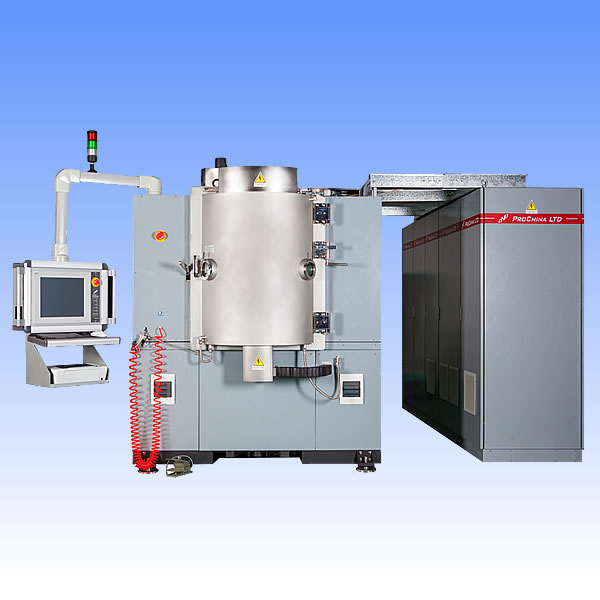

ES500 is a surface coating equipment by aluminum on NdFeB. The traditional method is generally treated by water plating, and the which problem is bad quality and polluted environment.we using the principle of vacuum coating, and the magnetron sputtering and the hot evaporation coating method to assist the high pressure ion bombardment and the rapid coating of compact aluminum film on NdFeB materials, ES500 technical specifications are listed as follows:

| Vacuum chamber dimensions | L1000mm * H1000mm * W700mm |

| Uniform platable area | Ø600mm * 700mm |

| Final vacuum | 3.0*10-4Pa |

| Pressure rising rate | 0.33Pa/hr(normality) |

| Cooling water | 5ton/hr |

| Occupied space | 4.0*3.0*3.5m3 |

| Vacuum chamber | 304 stainless steel of Japan and Korea, double layers and five-year warranty |

| Pumping system | Leybold diffusion pump+Leybold roughing pump+Roots pump |

| Vacuum testing | SKY90 compound vacuum gauge |

| Traffic control | Sevenstar Electronics’ 7S-CS200 digital flowmeter/Brooks/MKS/AE |

| Swivel | 大网笼带一次自转和小网笼带二次自转,保证工件之间无磕碰接触 |

| Magnetron sputtering | 1 sets of columnar sputtering targets |

| Evaporator boat | 5 sets boron nitride evaporation boat. |

| Wire feeder | Wire feed speed is adjustable to ensure different evaporation deposition rates |

| Bombard power | Up to 3000V |

| Heating system | 300 degrees at most, 2 thermocouples for supervision |

| Cooling water circulation system | equipped with Japanese SMC water switch, intelligent control. |

| Electrical element | air switch and contactor switch of Japanese Omron PLC, JST, Schneider, etc. |

ProChina vacuum coating machine equipments are designed and manufactured strictly under standard and specification of CE of the EU.

Request Quotes and Solutions:huzhongjun@naura.com

Sharing:

京公网安备 11010502053715号

京公网安备 11010502053715号