Watch industry Coating Solution Position:Home > Solutions > Watch industry

● Based on the characteristics of products in watch industry and increasing customer demands, we have continuously developed various equipment technologies and coating processes (more wear-resistant, brighter, etc.)

In watch industry, PVD technology, especially ion plating (IP) technology is mainly applied to the surface treatment of watchcases and straps. Compared with traditional water electroplating technology, IP ion plating is free from discharging three wastes and high toxicity (cyanide) during the production, which is environmentally friendly as a green technology. Moreover, the plating performance is also far more than water electroplating with high IP ion plating purity, uniform thickness, good compactness, excellent bonding force and better wear resistance. The application of IP in watch manufacturing industry has greatly improved the wear time of exterior coating of watch, which has, to a certain extent, promoted the development and progress of watch manufacturing industry.

At present, common IP ion plating technologies include: ion plating gold (IPG), ion plating rose gold (IPRG), ion black plating (IPBlack), and ion plating steel (IPS). The IP ion plating technology for gold plating not only saves the amount of gold, but also improves the wear and corrosion resistance of coating, which greatly improved the service life of coating. A large amount of research data shows that IPG gold coating (thickness is 0.1-0.2 μm), whose thickness is only 1/50 of that in traditional aqueous gold plating layer (thickness of 5 μm), is 3 to 4 times longer than the wearing time of traditional aqueous gold plating layer.

IPG-is to deposit a 0.8-1.0 μm layer of TiN coating on substrate as bottom layer, and cover a 0.1-0.2 μm gold layer on the TiN coating. According to the different colors, gold layer color is divided into 1N color, 2N color or 3N color, IP gold layer is in uniform color and beautiful with temperature performance up to 500 °C, the normal wear and use time can achieve more than two years.

IPRG- is to deposit a 0.8-1.0 μm layer of TiCN coating on substrate as bottom layer, and cover a 0.1-0.2 μm rose gold layer on the TiCN coating. According to the different colors, rose gold layer color is divided into 4N (flour gold) color and 5N color (red gold), IP gold layer is in uniform color and beautiful with temperature performance up to 175 °C, the normal wear and use time can achieve more than one year.

IPBlack- is to deposit a layer of black coating on the substrate. Usually the elements of this black coating are mainly C elements, doped with some proportion of metal elements to form various coating compositions, such as TiC +C, CrC+C or DLC, etc.

IPS-is to deposit a hard chromium coating of stainless steel on the substrate. This hard chrome coating is stable in the atmosphere that it can maintain its luster with high hardness, abrasion resistance, corrosion resistance and heat resistance.

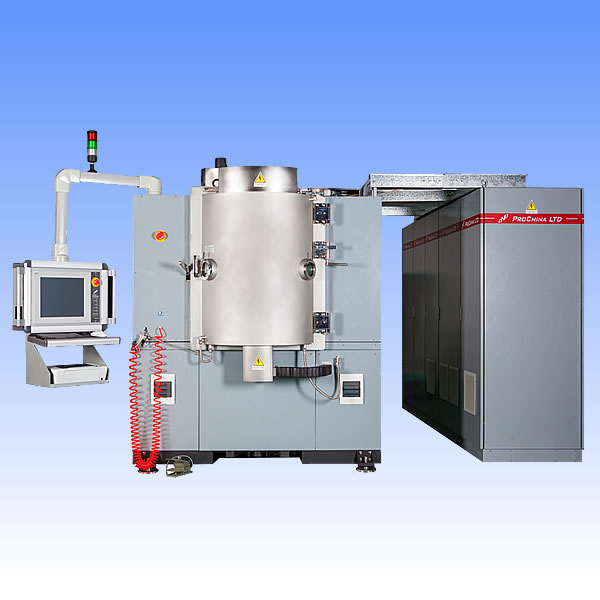

Applicable equipments

● AS4GX

Coating Sample

京公网安备 11010502053715号

京公网安备 11010502053715号