Gear cutter Coating Solution Position:Home > Solutions > Gear cutter

● The service life of coatings of gear cutters can reach the top level in the domestic market.

As the name implies, a gear cutter is a kind of tool for machining gear, which is widely used in fields of industrial production. Just as the rest of industries at present, gear cutters are developing to be environmental protective, highly efficient and low-cost.

The traditional wet processing adopts the cooling liquid, which will produce a large number of oil mists in the machining process, harming the health of operators. And the dust and oil mist emissions will pollute the environment seriously. On the other hand, dry cutting need no cooling liquid, which is environmental friendly and reduces the costs of gear hobbing machining. A higher cutting speed is also adoptable, improving the efficiency. Of course, dry cutting requires better tools and coating.

In the present market, the commonly used PVD coating of gear cutters can be divided into three types: TiN coating, whose gear hobbing speed is 20~60m/min; TiAlN coating, whose gear hobbing speed is 60~120m/min; AlCrN coating, whose gear hobbing speed is higher than 120m/min.

As for high speed steel hobbing cutter, ProChina adopts 4G-CAE technology, cooperating with the plasma etching technique of GIS and the magnetron sputtering technology of MS, so as to plate AlCrMeN, which not only has good resistance to oxygenolysis, high temperature wear resistance and diffusion ability. It has reached the international advanced level of coating technique in the actual cutting test.

Shanghai Automobile Gear Works produces AlCrN hobbing cutter with the PVD coating technique of ProChina under the same conditions of manufacturing techniques and machining parameters, which has reached the same output (beat) and machining accuracy requirements of Swiss Balzers company.

A machinery factory in Banan of Chongqing produces TiAlN coating hobbing cutter with the PVD coating technique of ProChina under the same condition of manufacturing techniques and machining parameters, which has reached the same output (beat) and machining accuracy requirements of Germany PVT company.

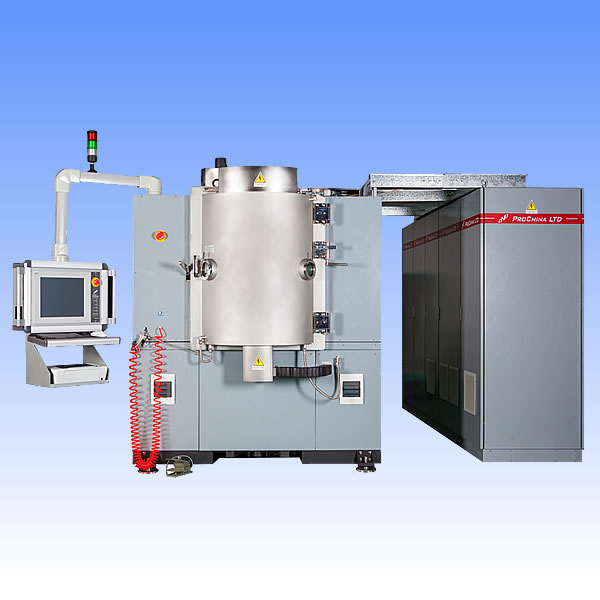

Applicable equipments

● AS700

● AS600

● AS500

Coating Sample

京公网安备 11010502053715号

京公网安备 11010502053715号