IVD Position:Home > Technology > IVD

Vapor Deposition technology is to put workpiece in a vacuum chamber, heat by certain methods, and then make the coating materials such as aluminum evaporate or sublimate, condensing into a membrane on the workpiece surface. The technique has advantages such as simple equipment, easy to control. But film layer through general thermal evaporation is coarser, whose adhesion strength is poor, and it's easy to form a bulky columnar crystal structure. Its corrosion resistant performance is not favorable. Normally, vapor deposition technology is seldom used for surface protection treatment, except a few foreign reports about Ion Vapor Deposition (IVD), to produce aluminum film.

IVD technology means to add negative bias on workpiece on the top of the evaporation source, producing glow discharge around the workpiece. In the process of evaporation coating, as evaporated metal vapor atoms pass through glow zone, part of the metal atoms is ionized into metal ions, accelerating the metal ions or atomic to move to workpiece surface to form film. The metal coating prepared by this technique has the advantages of good compactness, high adhesion with base and fast deposition rate. Therefore, this technique can be applied to the preparation of corrosion resistant film layer.

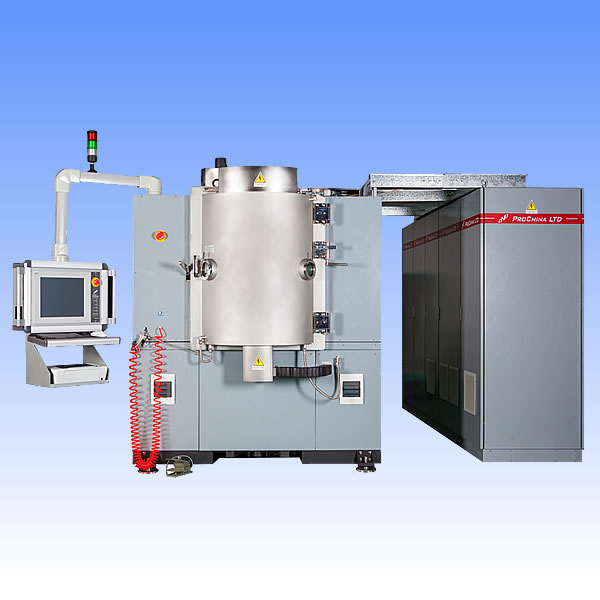

ProChina has developed an ion beam assisted evaporation system with continuous wire feeder, which can control the evaporation rate by adjusting the wire feeding rate and its deposition rate of aluminium film can reach 20 microns/hour. Under the effect of ion beam assisted evaporation system in vacuum chamber, the compactness, adhesion of deposited aluminum film can reach the requirements of corrosion resistant films. Aluminum anti-corrosive coating on the surface of Nd-Fe-B materials can pass the industrial quality certification.

Ion beam assisted evaporation system with continuous wire feeder

京公网安备 11010502053715号

京公网安备 11010502053715号