Hard coating Position:Home > Products > Hard coating >

- Detail

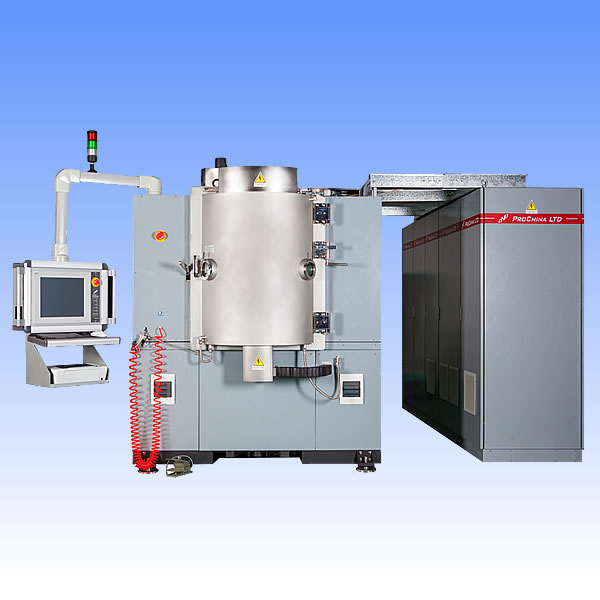

AS700 is developed for coating service and tools companies. It's a simple structure and large load. Specific as follows:

| Vacuum chamber dimensions | Ø900mm * H1200mm |

| Uniform platable area | Ø700mm * H800mm |

| Ultimate vacuum | 3.0*10-4Pa |

| Pressure rising rate | 0.33Pa/hr(normality) |

| Cooling water | 6ton/hr |

| Occupied space | 4.5*4.0*3.5m3 |

| Vacuum chamber | 304 stainless steel of Japan and Korea, double layers and five-year warranty |

| Pumping system | KYKY Molecular pump/Edwards/Leybold magnetic molecular pump+Leyboldroughing pump+Roots pump |

| Vacuum testing | Inficond diaphragm gauge+SKY90 compound vacuum gauge |

| Traffic control | Sevenstar Electronics’ 7S-CS200 digital flowmeter/Brooks/MKS/AE |

| Swivel | removable down swivel (4, 5, 6, 8, 9, 12 axis, Choose one) |

| Cathodic arc | 4 groups(16 sets) of 4G-CAE (target material specification 100*20) at most |

| Grid bias power supply | Huettinger Bias 26KW/PLS-30KW |

| Smart source baffle | 1 set, prerinsing the target material before coating. |

| Heating system | 500 degrees at most, 3 thermocouples for supervision |

| Cooling water circulation system | equipped with Japanese SMC water switch, intelligent control. |

| Electrical element | air switch and contactor switch of Japanese Omron PLC, JST, Schneider, etc. |

Optional configurations are as followed:

1、Standard fixture

2、Accessory equipment such as special workpiece oven, water chiller and sand-blasting machine

Request Quotes and Solutions:huzhongjun@naura.com

Sharing:

京公网安备 11010502053715号

京公网安备 11010502053715号