On magnets Coating Solution Position:Home > Solutions > On magnets

● Combining the characteristics of the rapid deposition rate of thermal evaporation and high quality of films through ion plating technology.

● The unique design of squirrel type structure ensures that the product has a full surface coating without any defect.

● Aluminum corrosion resistant coating of NdFeB surface made through the technology has acquired the market certification.

NdFeB is a kind of lanthanon permanent magnet materials. With PVD technology, to aluminize on the surface of NdFeB as a protective coating is one of the effective and reliable methods to improve its corrosion resistance. Comparing with traditional electroplating and chemical plating, PVD technology is an environmental protective one. Moreover, it can address the technical defects of electroplating and chemical plating, such as the quality problems caused by the electrolyte residuals. What’s more, PVD coating is featured by fine grain and even film thickness and excellent film-substrate cohesion.

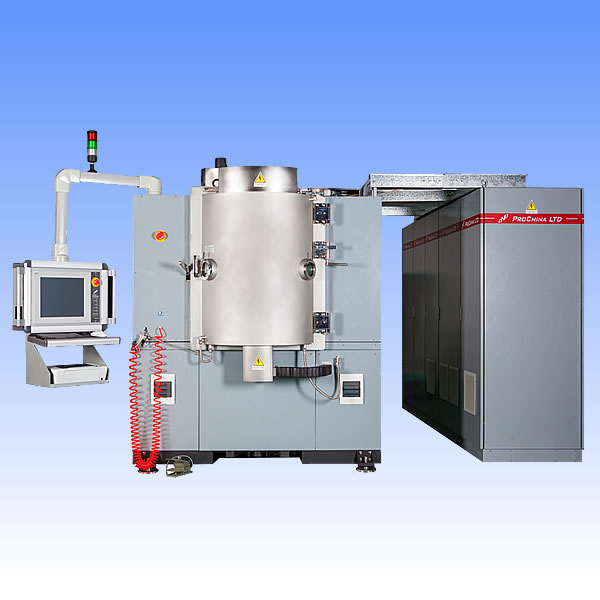

ProChina has develop an ion-assisted vacuum evaporation aluminizing equipment specialized for NdFeB plating with partners. This equipment has broken the technological monopoly of the United States and Japan. Aluminum protective coating using the plating technology can meet the market requirements of magnetic solid boot performance index.

The equipment is featured by the following:

1. Using ion-assisted evaporation coating technology can solve the problems of poor adhesion and loose films.

2. Using the continuous feeding technology that can adjust the speed can adjust the plating rate and the maximum deposition rate can reach 20 microns per hour.

3. Horizontal rolling cage method is adopted to clamp the products, which solves the problems of mounting point of traditional vertical clamping.

京公网安备 11010502053715号

京公网安备 11010502053715号