4G-CAE Position:Home > Technology > 4G-CAE

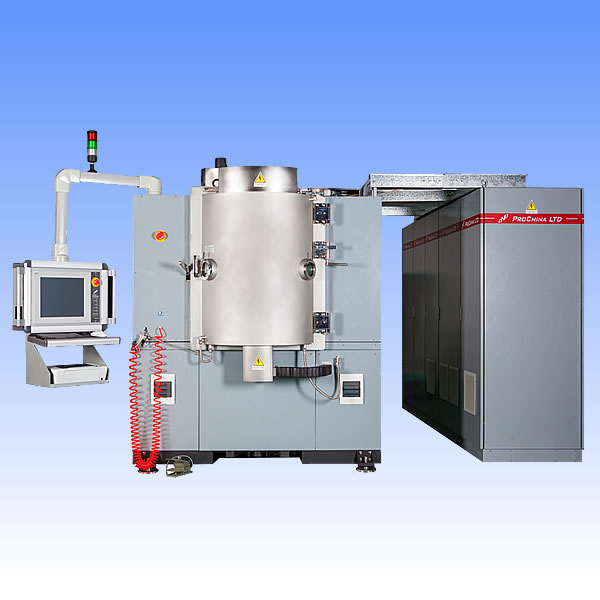

The 4G arc technology of ProChina has achieved great effect in the field of tool plating. The quality of film they produced can compete with that of foreign coating companies, also establishing the domestic leading position of the coating equipment of ProChina. This technology adopts special electromagnetic field design, driving arc spot to move faster, to stay at the same location for shorter time. Arc spot is smaller with less monomer energy, reducing the size and quantity of micro-droplet effectively; At the same time, the number of discharging arc spots is bigger, resulting in stronger plasma. Under the drive of electromagnetic field, the density of plasma in vacuum chamber is greatly enhanced, improving the environment of ion reaction coating. The decreased micro-droplet has improved the surface brightness of the arc coating greatly, and the color of the film is more saturated.

The following video demonstrates the different states of the 4G-CAE closing and opening the electromagnetic coils.

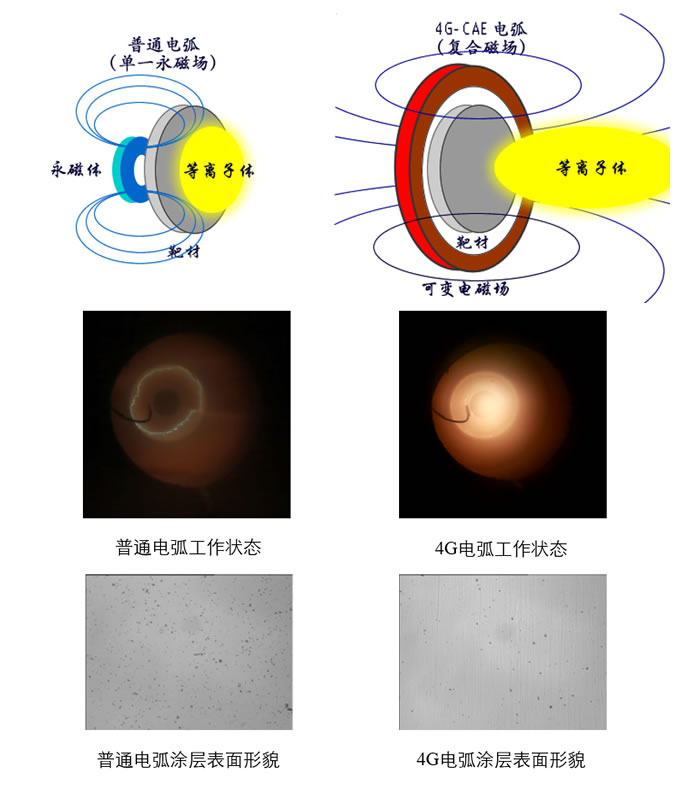

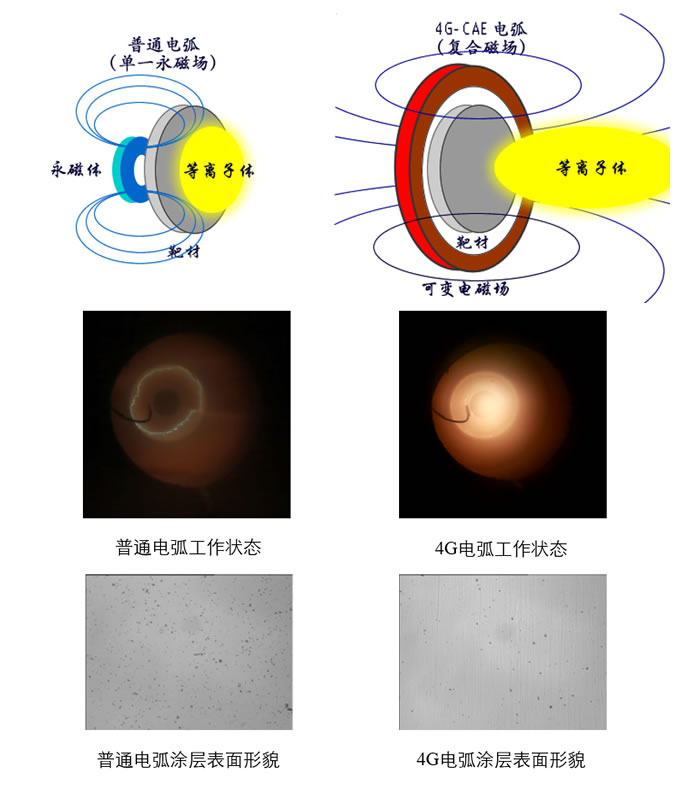

Complex magnetic field

To enhance the density of plasma

Under the strong magnetic field, cathode arc discharges to generate plasma near the surface of the target material, which will be pushed to the coating area, enhancing the density of plasma in vacuum chamber greatly, improving the environment and conditions of reactive ion plating film; Thus, the quality of reactive ion plating film can be improved significantly.

To suppress “micro-droplet” effectively

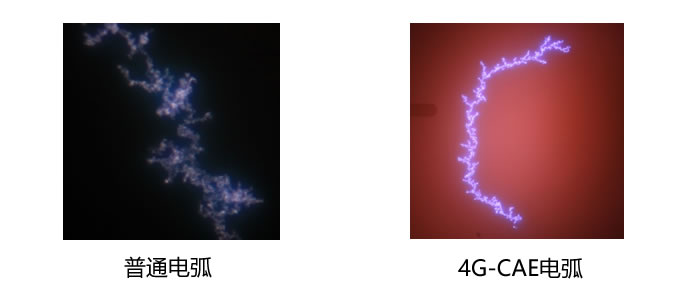

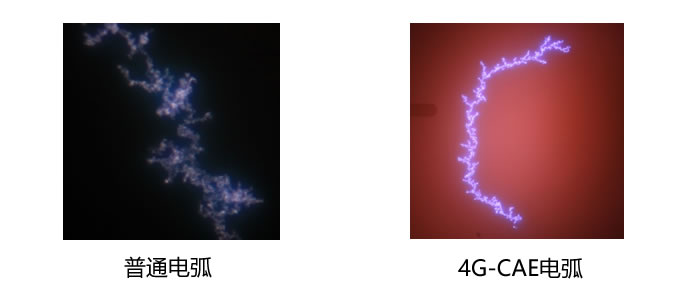

1、Under the drive of the powerful and variable electromagnetic field, the arc spot will not only run fast along the target ring, but also move back and forth along the diameter; it makes the arc spot run faster, and each arc spot smaller (as picture below left shown), the number of arc spot bigger. Reducing the size of "micro-droplet" and the number of large droplets can make the coating layers more delicate and luster.

2、As for a large number of alloy targets containing Al, such as AlTi alloy target, AlCr alloy target, 4G-CAE arc technology shows great effects in suppressing Al drops!

To improve the utilization rate of the target material.

The actual discharging condition of 4G-CAE: under different discharge current (95A or 150A), the continuous discharging for 1 second enables the control of even distribution of arc spots on the target surface.

High utilization rate of target material of 4G-CAE: using the characteristic that the strength of electromagnetic field can be adjusted easily to prepare arc spots to move back and forth along the diameter of target direction, in order to realize an evener ablation of target, improving the utilization rate of target material. The utilization rate of the target material can reach 70%.

The following video demonstrates the different states of the 4G-CAE closing and opening the electromagnetic coils.

京公网安备 11010502053715号

京公网安备 11010502053715号