Key component Coating Solution Position:Home > Solutions > Key component

● ProChina can provides DLC coating equipment for key parts, tools and other applications.

The trend of modern mechanical industry leads to more requirements on mechanical parts: to reduce the consumption and to increase the efficiency of workpiece, to strengthen load and reliability of workpiece, to prevent damaging the environment and to reduce the use of lubricant. These trends exert more pressure on the surface of workpiece. Heavier loads and reduced lubricant will accelerate the abrasion on the surface of workpiece.

With the rise of Chinese manufacturing industry, any subtle improvement in technology could promote the competitiveness of enterprises. PVD coating can also leverage good performance in many key components. For instance, its low friction coefficient enables the poston of manufactured stirling cryocooler to reduce friction and improve abrasive resistance, meeting the requirements of oil-free lubrication and duration.

Replacing the original durionise with PVD coating on rotating shuttle(parts of a sewing machine can not only avoid the environmental pollution, but also improve the surface hardness and abrasive resistance, improving the service life by over 10 times. Also, because of the lower friction coefficient of the coating surface, it produces lower noise in performing.

Take China's booming auto industry as another example. The country has put forward higher requirements on energy conservation and emissions reduction and manufacturing process. PVD vacuum can be used in the surface treatment and production of auto parts, completely or partly replacing the traditional chemical plating and providing auto parts enterprises with solutions of key basic equipment and a set of coating production line of "near zero emissions", so as to realize green manufacturing of the surface treatment of automobile parts.

ProChina applies innovative material system and the related patent coating technology to research and develop highly adhesive, highly temperature resistant, abrasive resistant films. It has improved the surface performance of many key components in many industries. Its effect has been optimized to address its problems of high temperature abrasion, anti-oxidant and anti-corrosion, lubrication, and service life. Under comprehensive tests, ProChina has taken the leading position in its performance indexes of the coating technology at home and abroad, forming the large-scale productivity.

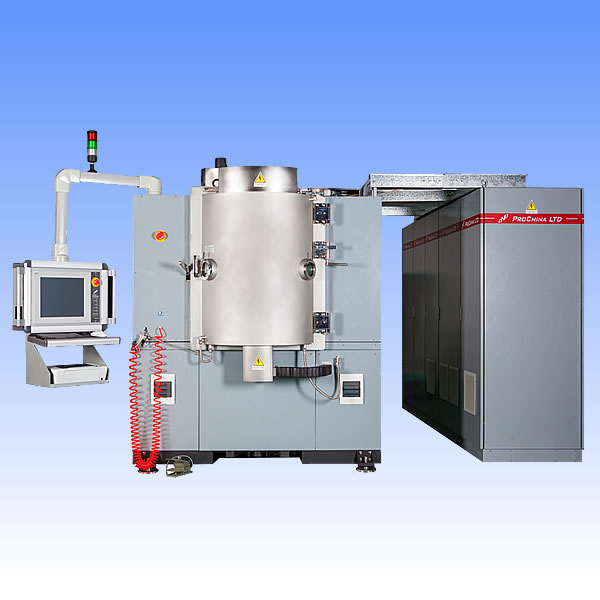

Applicable equipments

Coating Sample

京公网安备 11010502053715号

京公网安备 11010502053715号