Mold industry Coating Solution Position:Home > Solutions > Mold industry

● To shorten production cycle and increase yield.

● To increase service life of mold by several times.

● Abrasion resistance and no deformation

● To strength the demolding properties

● To improve the liquidity of raw materials and optimize the quality of finished products.

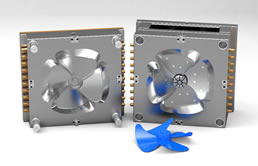

Plastic molds

Due to high requirements, the duration of plastic molds are concerned. For instance, the fiber in plastic tends to abrade the surface of mold, or it is required to lubricate when demolding. PVS coating can address the problems with its unique lubricity and hardness.

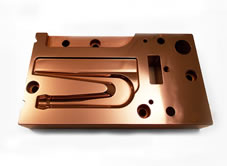

BeCu mold or mold insert

BeCu is featured by quick heat dissipation, which can reach to Rockwell hardness of 40. Quick heat dissipation means that it can shorten the production circle of injection molding with higher yields. BeCu is more expansive than ordinary plastic and steel, so the cost of any abrasion, scrapping or sharpening is high. As it cannot surpass the Rockwell hardness of 40, the surface abrasion is a serious issue.

Considering the hardness and other features of BeCu, ProChina has designed a complete PVD coating plan for BeCu mold or mold insert, in hope to improve the resistance against abrasion of BeCu surface and to maintain its high thermal conductivity.

Precision mold or mold insert

Currently, popular consumer products such as digital cameras, laptops, mobile phones and others have many functions, while their sizes are getting smaller and more exquisite, so this kind of products has high requirements on precision and the choice of materials. As for the selection of materials, due to the protection of shells and strength inside, PC+ABS+ fiberglass materials are generally adopted. However, the material tends to abrade or corrode molds, so they are abraded fast, and the price for maintaining precision mold is high. While precision mold inserts are characterized by fewer errors and more deep grooves. It is uneasy to maintain non-deformation and coating. ProChina knows anything about the coating application of the molds, and its application plans can solve the problems for customers.

Nylon or mass production of mold

1) A transparent plastic bottle is a typical product of mass production. Its mold has high requirements in surface under quick production, such as high hardness of surface, polishing to mirror surface and good demolding capacity. Due to the high hardness and good lubricating property of PVD coating, it can shorten the manufacturing circle and improve the yield.

2) Nowadays, automobile manufacturers are trying to reduce the total weight of their automobiles without compromising safety and quality, so as to achieve fuel efficiency. Engineering plastics are light and hard, which are good materials for auto parts, but when it comes to produce engineering plastics such as nylon or fiberglass, the surface of any type of steel is particularly abrasive. To extend their duration, manufacturers are willing to use PVD coating. After knowing the benefits of PVD coating, a large manufacturer of auto parts molds and products has adopted PVD coating for all the molds of nylon auto parts, improving the service life.

Hardware mold

Mold industry can be divided into: hardware mold, plastic mold, casting mold. As for hardware mold, the hardware industry generally needs to punch in the metal sheet, bend and so on. Frequently-used punching parts, such as punches tend to be rubbed against the processed materials. In order to extend its service life, most of them require PVD coating.

Casting mold

The production conditions of casting mold are the most severe. In hot metallic solution, high pressure injection and constant thermal expansion of the surface heat lead to the short service life of casting mold. In producing, it needs repairing and maintaining. Considering the problems, ProChina has researched and developed a new technology of the pretreatment of PVD coating, achieving remarkable results in improving the mold sticking of liquid metal and thermal cracking.

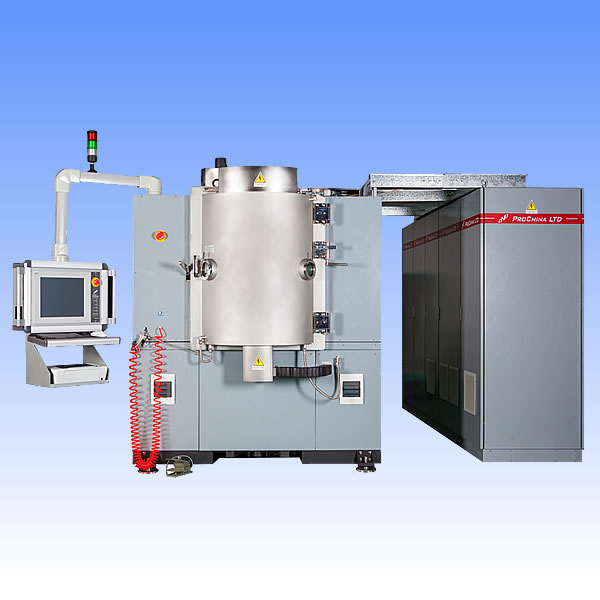

Applicable equipments

● AS700

● AS600

● AS500

Coating Sample

京公网安备 11010502053715号

京公网安备 11010502053715号