Surface metallization Coating Solution Position:Home > Solutions > Surface metallization

● Increasing the service life of products by 3-4 times.

● hard, abrasion-resistant, corrosion-resistant and thermal-resistant.

● Ever bright as new

The application area of non-conductor represented by plastic and ceramics is getting wider, which has high requirements in nonconductor products. After the surface metallization of non-conductor, it has the advantages of both metal and non-conductor. Replacing metal parts with non-conductor such as plastics, ceramics can have the metallic appearance and reduce the weight, saving the metal. As for plastics, it can also use injection molding to improve labor productivity. Non-conductor has better corrosion resistance than metal conductor plating pieces. Metallization can improve anti-aging property, anti-chemical solvability, and abrasion resistance and thermal resistance.

Surface metallization applications of non-conductors can be divided into two categories:

First is decorative application. It is widely used at home and abroad from daily light industrial products, electronic equipment industry to automobile manufacturing industry.

Second is functional application:

1. To process the printed circuit board;

2. To produce antenna conductor and enact electromagnetic shielding for instruments;

3. The metallization of chips can prevent the adsorption of particles and oil stains;

4. It is widely used in semiconductor assembly technology, especially in making multiphase transformation electrodes or variable resistor memory equipments. For example: it can be made into sulfide of memory properties;

5. Some military electronic equipment such as radar sometimes needs to penetrate electromagnetic wave, such as radome. And the transmittance is bigger, the better. To avoid divergent transformation, some need to reflect electromagnetic wave, such as reflector of radar antenna, and some need to absorb electromagnetic waves, such as advanced composite materials with stealth capabilities, etc. Generally, the reinforced resin matrix composites have a good electromagnetic wave transmittance. If it is adopted to the antenna reflector, metallization of the surface is required;

6. It is also widely used in insulating porcelain of capacitor.

Surface metallization can be realized through many other ways except electroplating technique, such as vac-ion plating and thermal spraying. With the improvement of technology, these methods can replace electroplating technology in some cases. Our company can apply metallic coating on ceramic surface, plastic surface and the surface of high polymer material using PVD technology.

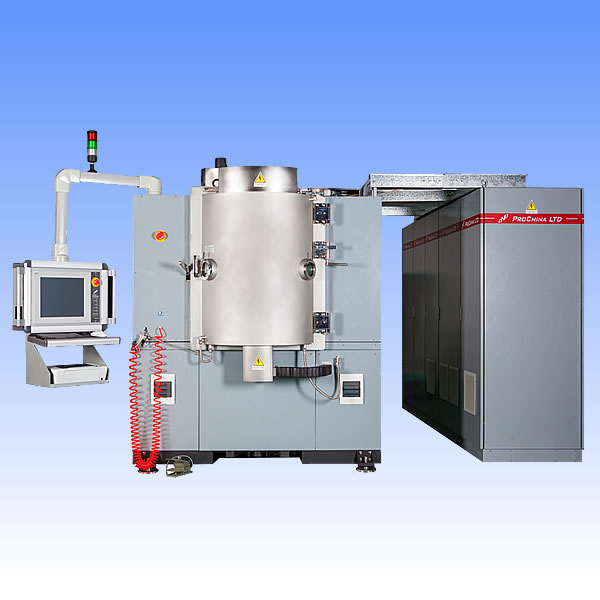

Applicable equipments

● AS4GX

Coating Sample

京公网安备 11010502053715号

京公网安备 11010502053715号