Sanitary ware Coating Solution Position:Home > Solutions > Sanitary ware

● ProChina provides coating solutions for several sanitary ware manufacturers and coating and converting companies, including Kohler, India.

PVD technology is a kind of surface treatment process developed rapidly in the past 30 years. There is no emission of three wastes (wastewater, waste gas and solid waste) in the entire PVD coating production process, nor any use and generation of toxic and hazardous substances (hexavalent chromium and cyanide). It is a green, environmental protection production technology.

PVD technology is widely used in the sanitary industry. It not only brings more colors and textures to sanitary products, but also brings superior performance. A thin (0.3-0.5μm) PVD coating will make the product wear-resistant and corrosion-resistant, and it perfectly solves the problem of scratching and color fading of sanitary products, making it lasting as new. At present, all the world's high-end bathroom brands are adopting PVD coating technology including foreign brands such as Kohler, Roca, Moen, American Standard, TOTO, etc., and domestic brands such as Jomoo, Arrow, HHSN, etc. According to preliminary statistics, about 5% of high-end sanitary wares (including faucets, showers, bathroom accessories, etc.) on the market currently use PVD technology for surface color processing. With people focus more on the quality, this ratio is constantly increasing year-on-year. Another point is that with everyone's concern for environmental protection, especially the need to replace water plating, the application of PVD will become wider and wider.

The main materials of bathroom products are stainless steel, copper alloys, zinc alloys and plastics, in which, only the surface of stainless steel can be directly coated by PVD, the rest ones should be electroplated (Cu, Ni, Cr) first, and then be coated by PVD. Due to the different temperature resistance of various materials, the coating process is very different. For example, the temperature resistance of the copper alloy is 180℃, and the coating can be completed in one pass. The temperature of the zinc alloy is 140 degrees, and the over-temperature phenomenon may occur when the coating is applied once. Bad foam, plastic parts only 60 degrees temperature resistance, to adopt a special coating process for temperature control. Damp Corporation can provide a full range of bath products production technology, including pre-treatment, PVD coating technology, production technology, and quality inspection technology.

In 2012, ProChina provided Indian Kohler a set of PVD turn-key projects, including a whole set of hardware and productive coating technology. It can coat all colors including imitated nickel color, various gold, gray black, stainless steel color, bronze, copper-color bronze under the requirements of Kohler on three materials(copper alloy, zinc alloy and plastics)

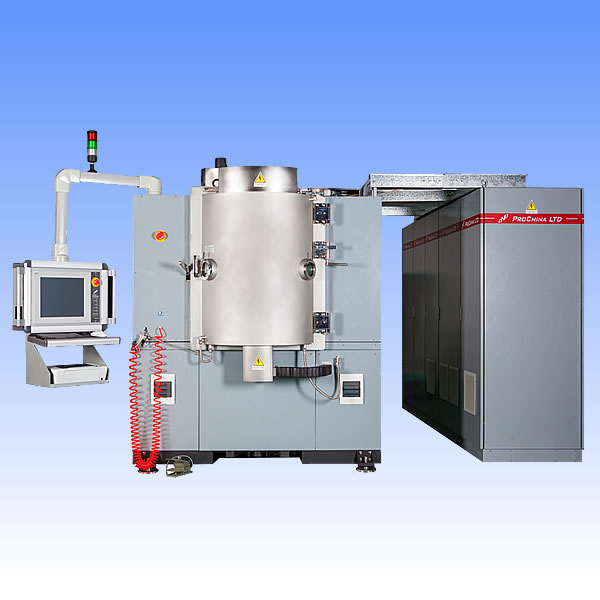

Applicable equipments

● AS1100D1GXL

● AS1100D5GXB

● AS1500D5GXB

京公网安备 11010502053715号

京公网安备 11010502053715号