PVD Position:Home > Technology > PVD

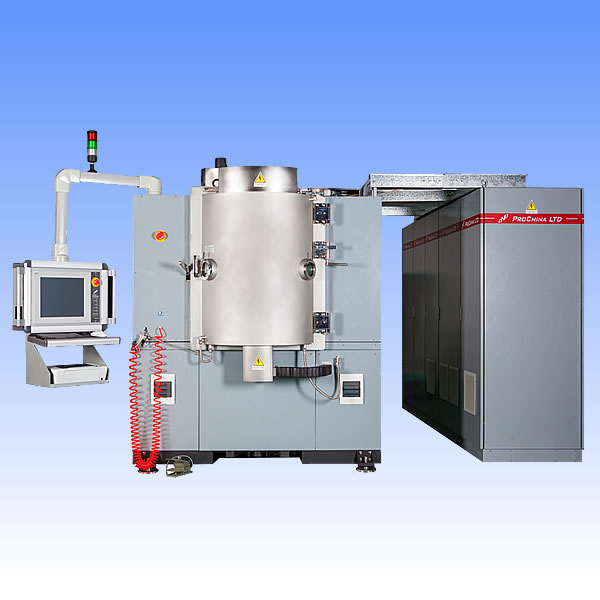

Vapor deposition is a technology that forms functional film on the substrate surface, which causes physical or (and) chemical reactions with materials, so as to deposit single or multiple layers, elemental or compound membrane layer on the surface of products, and provide the surface of product a variety of excellent performance.

As a surface coating method, vapor deposition is carried out through the basic procedures of gas phase -> transportation -> deposition. Its main characteristic is that no matter the materials to be plated are solid, liquid, or gas, they need to be converted in the gas phase for transportation, and eventually reach the surface of workpiece for depositing into a solid film.

Vapor deposition is mainly divided into two categories:

Chemical Vapor Deposition, CVD for short;

Physical Vapor Deposition, PVD for short.

Initially, people heat volatile liquid TiCI slightly to gain TiCI gas and NH gas which are guided into high temperature reaction chamber guide for decomposition. Then, chemical reactions are carried out on the sold surface in high temperature under thermodynamic principle, generating TiN and HCI. As HCI is siphoned off, TiN deposits into hard solid film on the surface. The process using volatile compounds containing membrane elements and gaseous substances to produce chemical reaction on the solid surface, and generate the non-volatile solid sediment is known as Chemical Vapor Deposition (CVD).

At the same time, another kind of vapor deposition that through heating metal or metal compounds at high temperature to evaporate into gas phase, or through electronic, plasma, photon and other energy particles to sputter corresponding atoms, ions, molecules (gas) from metal or compound, depositing a solid phase membrane on a solid surface, which has nothing to do chemical reactions (decomposition or combination) is known as Physical Vapor Deposition (PVD).

With the development and application of vapor deposition technology, the two types of vapor deposition have new technical contents, which are interlocked with each other, making it difficult to distinguish between chemistry and physics clearly. For example, people introduce plasma, ion beam into the evaporation and sputtering of traditional physical vapor deposition technology of for coating. Meanwhile, reaction gas is feed to carry out chemical reaction on solid surface, generating new solid phase membrane of synthetic product, which is called reaction plating. Feeding reactant gas into sputtering titanium (Ti) plasma to combine TiN is an example. Namely, physical vapor deposition can also contain chemical reactions. For example, feeding methane into the reaction chamber, and by w target cathode arc to discharge, methane is decomposed under the action of Ar and w plasma,and restructure the carbon bonds on the solid surface, to produce diamond-like carbon film with W. People used to classify the deposition process into chemical vapor deposition, but it is a typical physical vapor deposition technology, as it is achieved in metal cathode arc ion plating. In addition, people introduce plasma and ion beam technologies into the traditional chemical vapor deposition process, so chemical reaction does not fully follow the traditional thermodynamics principle, as the plasma has higher chemical activity, which can react at lower temperature than that in the traditional chemical reaction of thermodynamics. The method is known as Plasma Assisted Chemical Vapor Deposition, PACVD for short; Some resources refer it as PECVD, which endows more physical meanings to chemical vapor deposition.

Nowadays, the difference between chemical vapor deposition and physical vapor deposition is the coating material forms. The former uses volatile compounds or gaseous substances, while the latter uses solid (or liquid) materials. This distinction seems to have lost its original meaning.

We tend to distinguish chemical vapor deposition and physical vapor deposition by the forms of plating materials according to the existing habits. To produce atoms, molecules, ions(liquid or plasma state )through evaporation at high temperature, sputtering, electron beam, plasma, ion beam, laser beam, arc and other forms of energy produced, depositing on the surface (including producing reaction product through chemical reactions with other substances in the gas phase). The process that generates solid phase membrane is known as physical vapor deposition.

京公网安备 11010502053715号

京公网安备 11010502053715号