GIMS Position:Home > Technology > GIMS

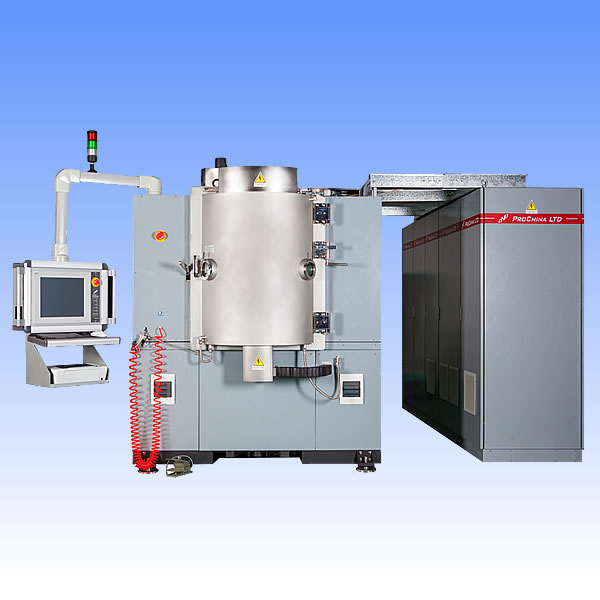

GIMS: Gas Ion Source Enhanced Magnetron Sputter can be divided into Focus GIMS and Separate GIMS.

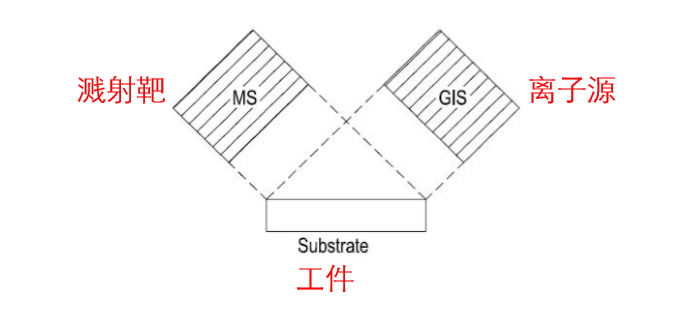

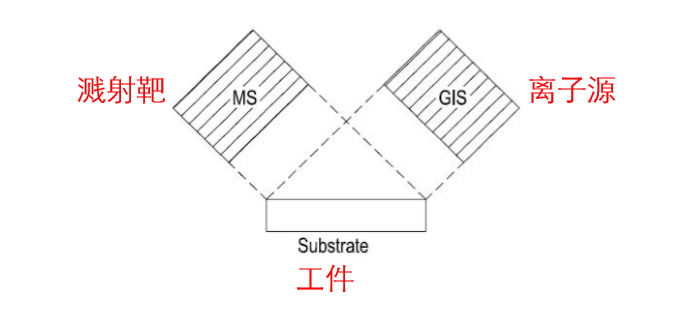

The working state of Separate GIMS

The function of ion source:

1. Plasma cleaning

2. Ionized reactive gas

3. Assisted deposition

4. Inhabiting target poisoning

5. Ion oxidation treatment

Focus GIMS

Gas ion source ionize and distribute gas to reactive gas. Under the electric field of ion source gas, plenty of gaseous ions gain kinetic energy (temperature) to move to the surface of workpiece, producing bombarding effect, so as to enhance the effect of the reactive ion plating film of the magnetron sputtering effectively. In the process of reaction coating, the gaseous ion bombards the surface of the workpiece, and the unstable ions on the surface are ejected, so as to “compact” the film structure, making it denser and smoother.

Applied to diamond-like coating (DLC), this technology has achieved very good results.

Separate GIMS

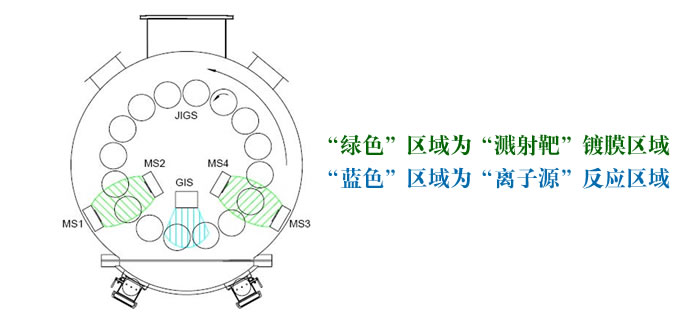

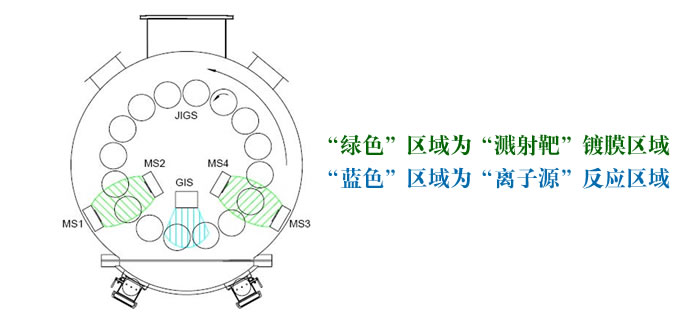

In the same Separate GIMS coating system, the gas ion source is transferred out of the coating area of the magnetron sputtering target. It can realize the separation of magnetron sputtering metal coating process and the reaction process of gas ion source ionization bombardment. Through magnetron sputtering to against target, a workpiece is coated with metallic film. Then as it moves to the front of gas ion source, bombardment reaction of reactive gas ion is enacted (such as nitriding). This is the so-called Separate GIMS.

It is effective to control the poisoning of sputtering target, making the reaction sputtering ion plating more controllable and the coating window wider.

The working state of Separate GIMS

京公网安备 11010502053715号

京公网安备 11010502053715号