● Outstanding capabilities in customer oriental equipment designing and manufacturing.

● Able to provide or assist clients in application development.

Over past 30 years, PVD ion plating is one of the most rapidly developing surface treatment technologies. PVD ion coatings with film thickness form 1 to 100 μm can improve the wear resistance, corrosion resistance, high temperature oxidation resistance and lubrication performance, and it has been extensively applied on aerospace and ordnance industries. Recently the aerospace industry increasingly concerns in reducing carbon emissions, maintenance costs and total operating costs, and in turn emphasizing on weight reduction, longer life, and fuel consumption reduction, the PVD coatings on those parts can play vital important roles to enhance their overall performances. Different from conventional surface treatments, PVD is an environmentally friendly green technology without any pollution problems.

Tolerant to more harsh environments

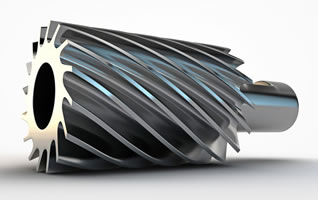

On metallic parts, coatings can help to extend parts’ service life and achieve higher benefits.

Coatings are usually applied to increase parts’ features, such as to provide thermal barrier or heat transfer under various load and temperature conditions and so on:

Typical areas of application include engine and mechanical parts, bearing and actuator.

● Reduce friction, wear, corrosion and abrasion

● High temperature hot corrosion

● Chemical inertness

Longer service life

Many parts in aviation industry will expose towards dust and dirt and subjected to various mechanical brushing and thermal shocks.

ProChina’s coating technology can reduce wear speed and extend service life of key parts and in turn the entire equipment, as well as prolong maintain cycles, reduce operational costs, lower spare parts inventory, and shorten maintenance time and complexity, so as to optimize costs and minimize the impact on environment.

● Increase surface hardness

● Self-lubrication function

● Low-wear characteristic

Diffusion films on turbine blade

As the hottest components on a jet engine, turbine blade will usually expose to extremely harsh environments. Even inside cold air-tunnel, the blades made of super-alloys might be still failure due to hot corrosion.

ProChina’s relevant solutions provide effective protection for the above critical parts. Contrary to conventional wrapping, PVD coated diffusion type aluminum-based films with uniform thickness and self-healing feature, can extend service life of turbine blades.

As well as composite base films or alloy films on customer special requirements.

● Able to operate under even higher working temperature

● Increase fuel efficiency

● Reduce hot corrosion

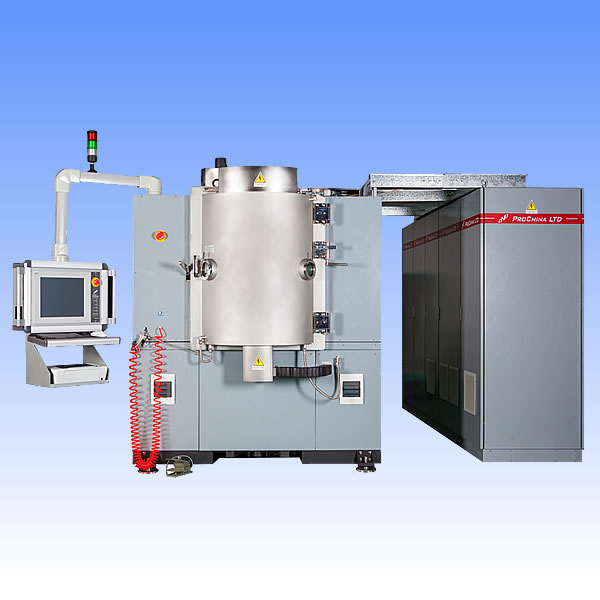

Collaboration with several domestic well-known enterprises and institutes, ProChina provides them high-quality PVD ion coating machines specially designed and manufactured. Major clients include: China Academy of Engineering Physics (9th Academy) , China Aerospace Science & Industry Corporation (Second Institute), Armored Force Engineering College, Guangzhou Research Institute of Nonferrous Metals, Chinese Academy of Agricultural Mechanization Sciences, etc.

The main applications include: hard coatings of cutting and processing of special materials, surface metallization of polymer and ceramic materials, surface anti-corrosion coating for special materials in nuclear industry, high-temperature oxidation coating for aero-engine blades, surface wear-resistant coating for key components such as engine bearings and spindles, and anti-corrosion coatings for aviation fasteners and key components.

Applicable equipments

● AS700

● AS600

● AS500

Coating sample

京公网安备 11010502053715号

京公网安备 11010502053715号